Designing 3 Phase LC-Filter For Power Factor Correction,

50kVAr, parallel to Rectifier Bridge

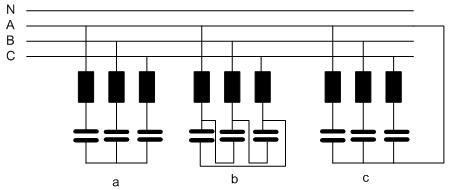

In the following picture there are 3 typical schemas of the LC resonance filters. The most used is the schema a. The schema b uses the capacitors with higher nominal voltage. If the LC filter current has 3. and 9. harmonic, then you need to use the schema c with 3 single phase chokes.

The LC filter for power factor correction is always connected on the 3 phase, 50Hz or 60Hz between the net and the load. The 50Hz or 60Hz current depends on the inductive power Q which has to be delivered :

I1 = Q/ph/U and Z1=U/I1

Where:

⦁ Q => inductive power of the LC filter

⦁ Pd => Number phases, normally ph=3

⦁ U => For star connection: U=Ua=Ub=Uc; for delta connection: U=Uab=Uac=Ucb

Z1 = L*Omega-1/C/Omega- where Omega =2*pi*f, f=> net frequency, 50 or 60Hz.

Normally the resonance frequency for LC filter is 189Hz for the net frequency 50Hz or 227Hz for the net frequency 60Hz net.

For these resonance frequency the ratio of the voltage Ul on the choke and Uc on the capacitor is approx. 7%.

Ul/Uc= 0.07 at net frequency

Now you know Z1. You can calculate C and L:

Xc = 0.93*Z1 and C=1/Xc/Omega

Finally :

Xl = 0.07*Xc and L = Xl/Omega

Due to the fact that the non-linear load is the source of the current harmonics which flow from the load to the net and the LC-filter, the distribution of these harmonics between the net and the LC-filter depends on the net short circuit voltage and the inductance L in the LC filter. It means that the values of the current harmonics through the LC filter has to be prescribed by your customer.

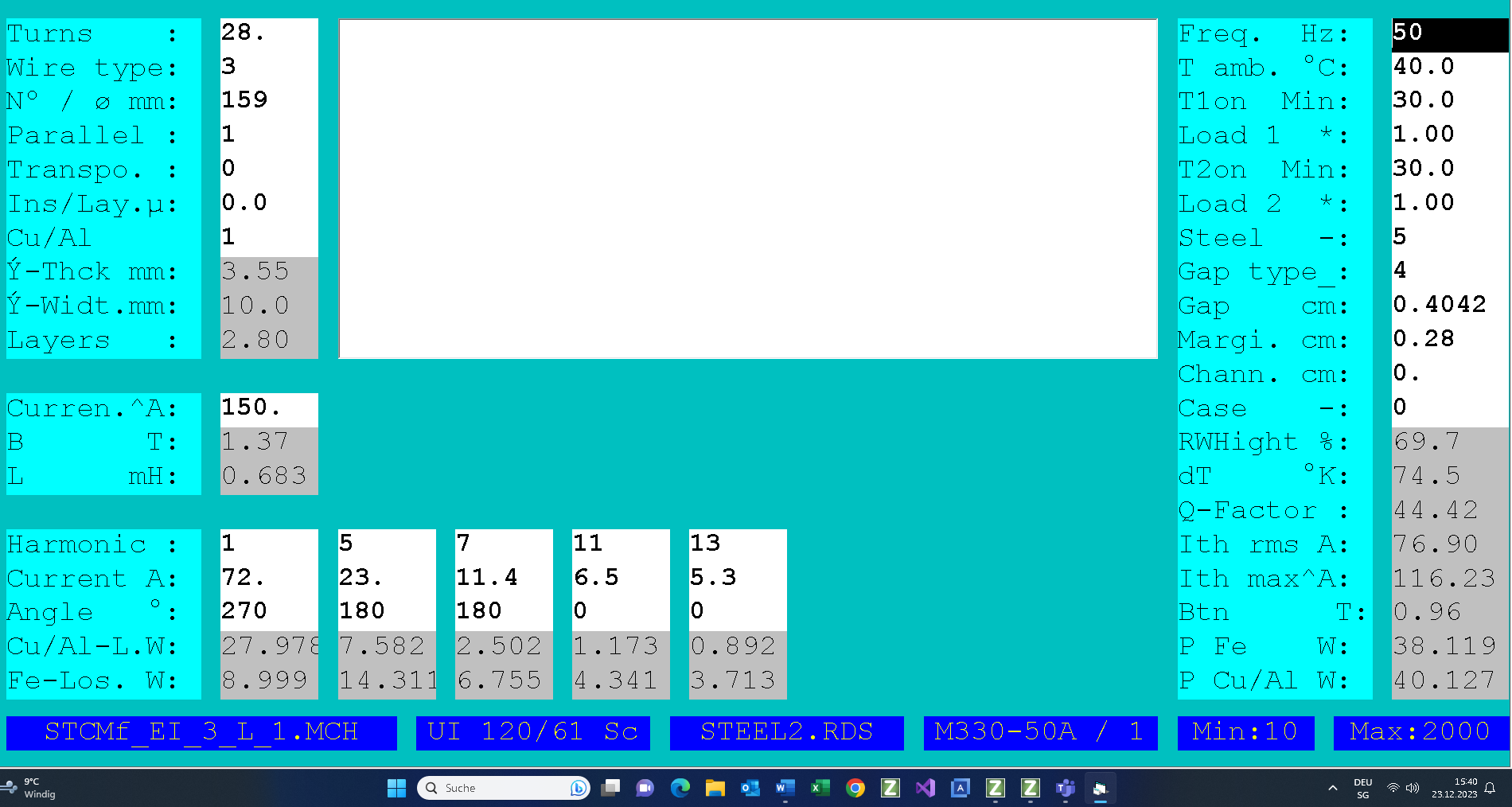

Creating the input for design of the choke:

Schema: a

Q=50kVAr

Nrt 3 x 400/230V, short circuit voltage at 200A = 5%V

U=230V

f=50Hz

ph=3

I1=50000/3/230=72A

Z1=230/72=3.2 Ohm

Xc=0.93*3.2=3Ohm

Xl=0.07*3=0.21 Ohm

L=0.21/314=0.687 mH

Assume the load is 3 phase bridge rectifier with the line currents:

Ir1=200A, Ir5=36A, Ir7=22A, Ir11=14A and Ir13=12A

and

Zn5=5*0.05*230/72=.8 Ohm,Zn7=1.12,Zn11=1.76 amd Z13=2.08

and

Z5=5”Xl-Xc/5=0.45 Ohm, Z7=1.04,Z11=2.03 and Z13=2.5

Now you can calculate the 5. current harmonic using :

Ir5=In5+I5 and

Z5*I5= Zn5*In5

or

I5=Ir5*(1+Z5/Zn5)

I5=23A, I7=11.4, I11=6.5 and I13=5.4

Note: If you want to use the schema b then you need to reduce tC sor the factor 3 and to select the capaxitor nominal voltage over 500V.

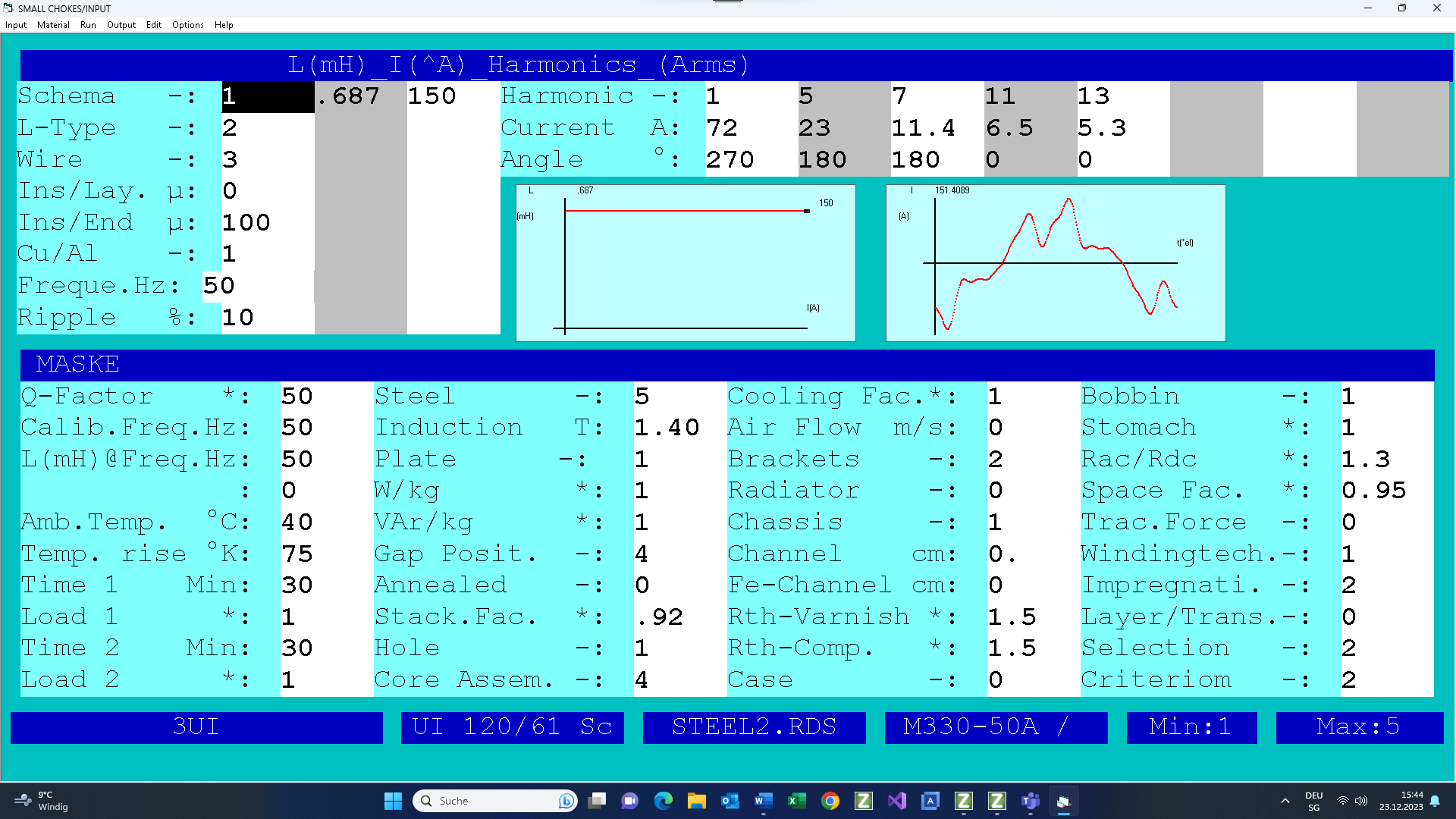

Input:

Set the inductance 0.687mH at peak current (View the peak value on the current diagram on the input screen). The resonance frequency is 189Hz for Ul/Uc=7%

· Select the AC inductance: L-Type = 1

· Select Cu flat wire: Wire = 3

· The frequency of the first harmonic is 50Hz

· Set the rms values of harmonics of the thermal current. Normally these harmonics need to be prescribed by your customer!

· Set the temperature rise 75°K and the ambient temperature 40°C

· Select grain oriented steel. Note that the induction will be optimized by program in order to get optimal relationship between core losses and winding losses,

· Set Gap = 4 and Core Assembly = 4 or better

· Select suitable 3 phase core family. If there are 3. and 9. harmonics (schema c) then you need to use 3 one phase cores.

· Use Al gap fixing plate: Plate=1

· Rac/Rdc=1.3

- Output – Control the value of induction, gap and connected wires in parallel;

- Test – Round the number of turns;

- Note – In order to calibrate the choke, connect it on the calculated calibration 3 phase AC-voltages (rms value) with the calibration frequency (normally 50Hz or 60Hz) and then vary the gap until you get the calculated calibration 3 phase AC-current (rms value).

TEST