How do we design a toroidal current transformer?

General information

You need to know:

• Nominal input current in A. I1

• Nominal output current in A. I2

• Output voltage in V Uload or output power P in VA, at the nominal current I2

• Current accuracy (class) in % c%

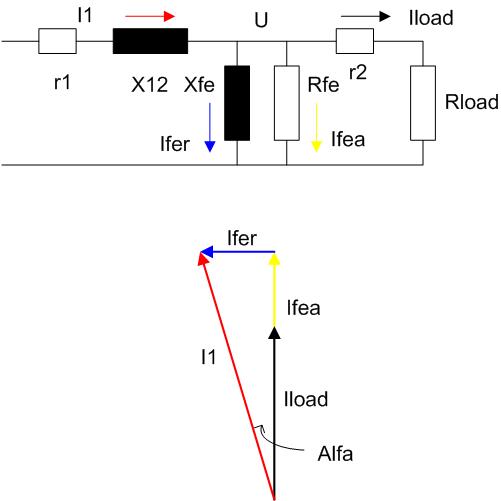

• Angle between the input and the output current Alfa in °

To eliminate the influence of the primary resistance r1 and the leaking impedance X12 between the windings, the secondary winding has to be wound first.=> inside

Before you start to run the program, you need to determine the following parameters:

• Core material

• Core sizes

• Induction at the nominal operation mode

• Number of the primary turns W1

If you want to design ONE-TURN toroidal current transformer, then you need to set:

W1=1 and W2= I1/I2

Now you are calculating the max. allowed magnetizing currents:

Ifea = c%*I2 /100 and Ifer = I2*tg (Alfa)

Normally the current transformer works in the linear part of the BH-magnetic diagram, in rolling direction:

B<K* W2*Ifer/l

The next condition uses the active losses in the core:

l*B<(4.44*f*Kc*W2)*Ifea/g/p

Legend:

– l => average core length in m

– g => core density in kg/m3

-p => specific core losses per kg at 1T and 50Hz

-K => rise of the magnetic curve B=f(Hrms) at 1T and 50Hz in Tm/Arms

-Kc =>Stacking factor

-f = Frequency

Design example

Creating the core:

1. Input current I1=200A

2. Output current I2=5A

3. Output voltage U=Ulosd+Ur=2.4V (in the program you need to use Regulation=20 Ur=0.4V)

4. Frequency = 50Hz

5. Class c%=1%

6. Angle Alfa= 1°,, tg(1°)= 0.01744

7. W1=1

8. W2=I1/I2=200/5=40

9. Core material grain oriented. annealed M97 = M5

10. K=B/H=1/12 Tm/Arms at 1T, 50Hz in rolling direction

11. p = 0.38 W/kg at 1T and 50Jz in rolling direvtion

12. g=7650 kg/m3

13. Ifea= c%*I2/100= 1*5/100 = 0,05A

14. Ifer= I2*tg(Alfa) = 5*0.01744 = 0.0872A

15. (l*B)r<K*W2*Ifer = 40*0.0872/12 = 0.29 Tm

16. (l*B)<(4.44*f*Kc*W2)*Ifea/g/p=4.44*50*0.95*40*0.05/7650/0.38=0.145 Tm

17. If B=0.7T then l < 0.145/0.7m = 204mm

18. Afe =U/4.44/Kc/f/W2/B =2.4/4.44/50/0.95/40/0.7 = ca 4.5cm2

19. The recommended core size is 50/80x30mm at the induction 0.7T

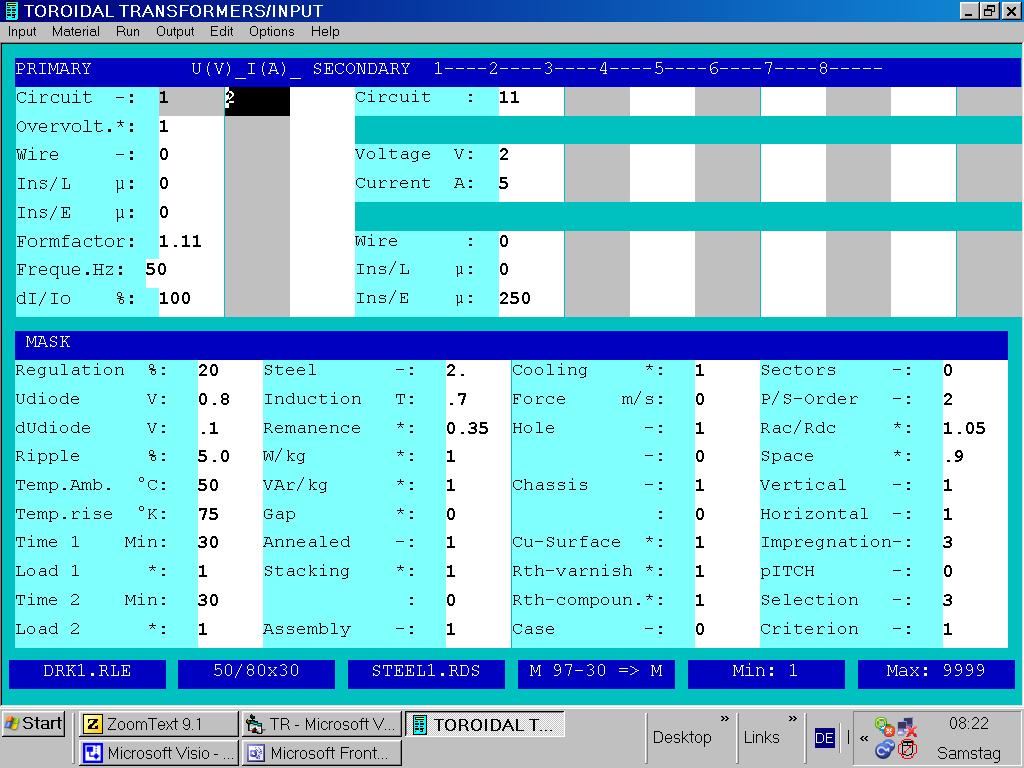

Creating the input in the design program:

Note that that the Toroidal Transformers Program supports the input of a power transformer. You have to know the input voltage, the output voltage and the output current. In order to run the program, you have to set primary voötage equel to the secondary voltage. At the end phase of the design you will come to the Test mode wherw you can manipulate the number of turns and the input voltage by hand . So you can similulate the IS operation mode of your current transformer!

To limit the inflence of the temperature in the value of the voltage drop on the secondary resistance r2, it is recommended to use the criterion of the design the regulation:

Criterion = 1 and Regulation<30%

P/S-Order = 2 =>SECONDARY WINDING INSIDE!

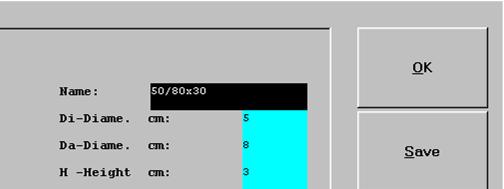

In the next step you need to create the core 50×80/30mm:

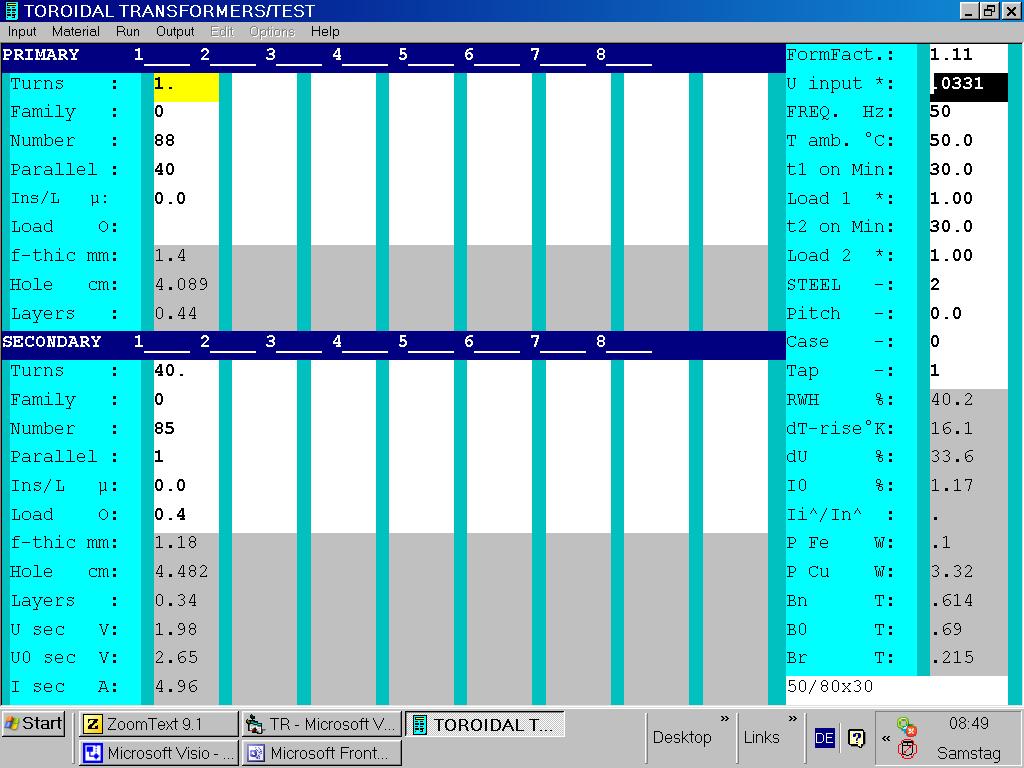

Run the program and open the Test mode.

Now you can change the turns of the primary winding W1=1 and the secondary winding W2 = 40 and vary the primary voltage in order to get I1=200A. The secondary current has to be I2>4.95A and the Angle<1°:

1. Set the input field U_input = 1/W2 = 0.025

2. Press F6 to run the Test mode

3. Set W1 =1

4. Number of the primary wires in parallel = W2 = 40

5. Number of the secondary turns W2=40

6. Press F6 to run the Test mode.

Now increase the the value of the input field U_input in order to get I1=200A and I2>4.95A or I2=4.95A and I1<200A.. In both cases the phase between the input and output current has to be <1°.

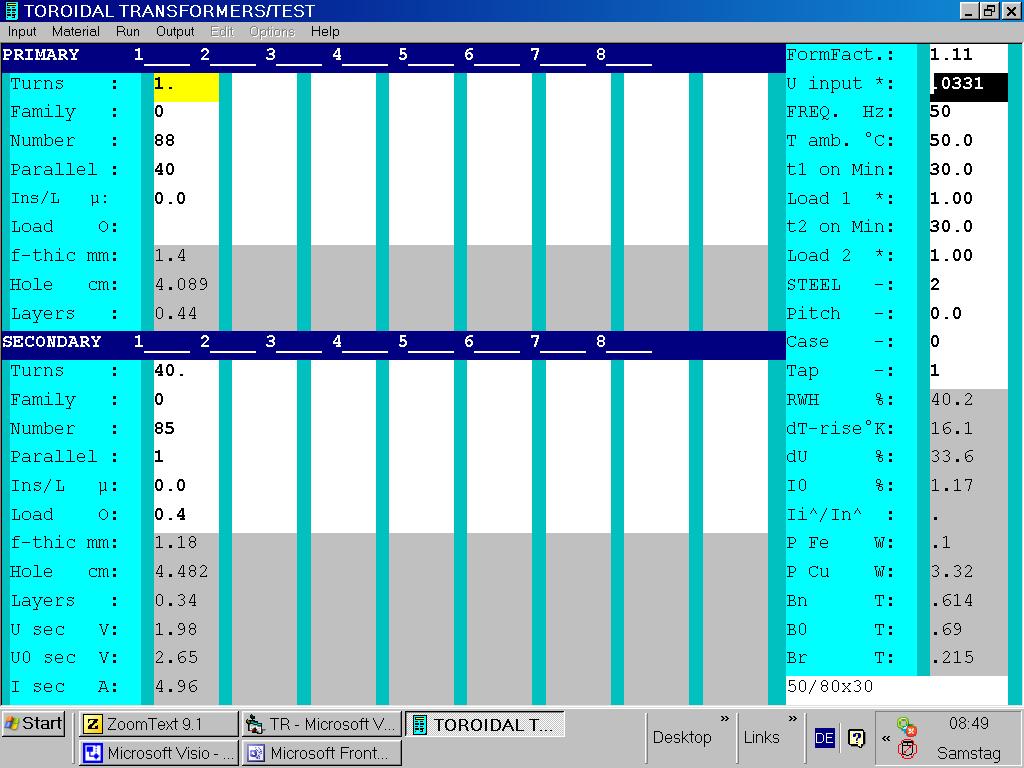

Finally here is the result of this design.

NOTE:

If the used core is too big then you can try to redesign this current transformer with the core 40/70x255mm at 0.8T

If you want to vary the input voltage you have to vary the primary voltage U_input.

At U_input=1 the primary voltage is 2V.

In the following table you can find the values of p and K for the steels which are supported in the Rale Design System:

| STEEL | Frequency Hz | INDUCTION T |

1/K A/T m |

p W/kg |

| M9-407/M5 | 50 | 1 | 12 | 0.38 |

| M75-23/M4 | 50 | 1 | 12 | 0.35 |

| 30P/10 | 50 | 1 | 9 | 0.345 |

| 27P95 | 50 | 1 | 9 | 0.29 |

| 23P90 | 50 | 1 | 9 | 0.29 |