CLICK HERE TO GET INPUT FILES: RaleInput_102_Foil RaleInput_102_Litz

Designing a 500 kVA, 50Hz, K-Factor 20, three phase dry transformer with litz & foil

General Information

Technical Specifications

| Input voltage | 3 x 400V, delta |

| Output voltage | 3 x 400/230V, star |

| Output power | 500kVA, K-Factor=20, continuous operating mode |

| Frequency | 50Hz |

| Ambient temperature | 40°C, in a cabinet |

| Temperature rise | Max. 120°K, insulation class H |

| °Short-circuit voltage Efficiency Inrush peak current factor |

Ø 1.5% 98.5% <8 |

| Core and steel | M6, annealed, strips for alternated stacking (45°) |

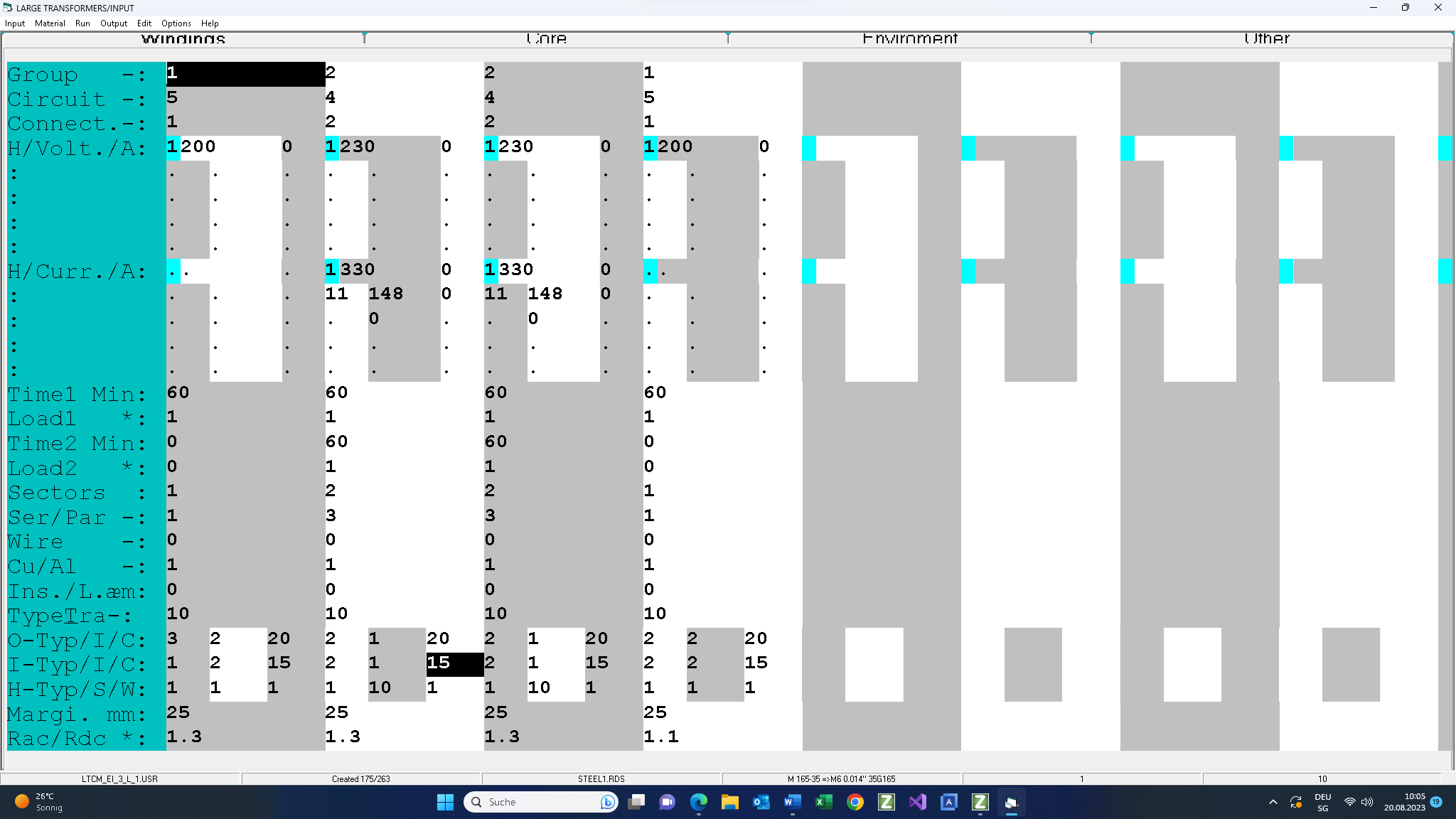

Creating Input

There are 4 input screens to set the input parameters for the designing of a transformer:

- Winding parameters per limb

- Core

- Environment

- Other parameters

and 3 screens for selection and set up of material :

- wires

- steels

- cores.

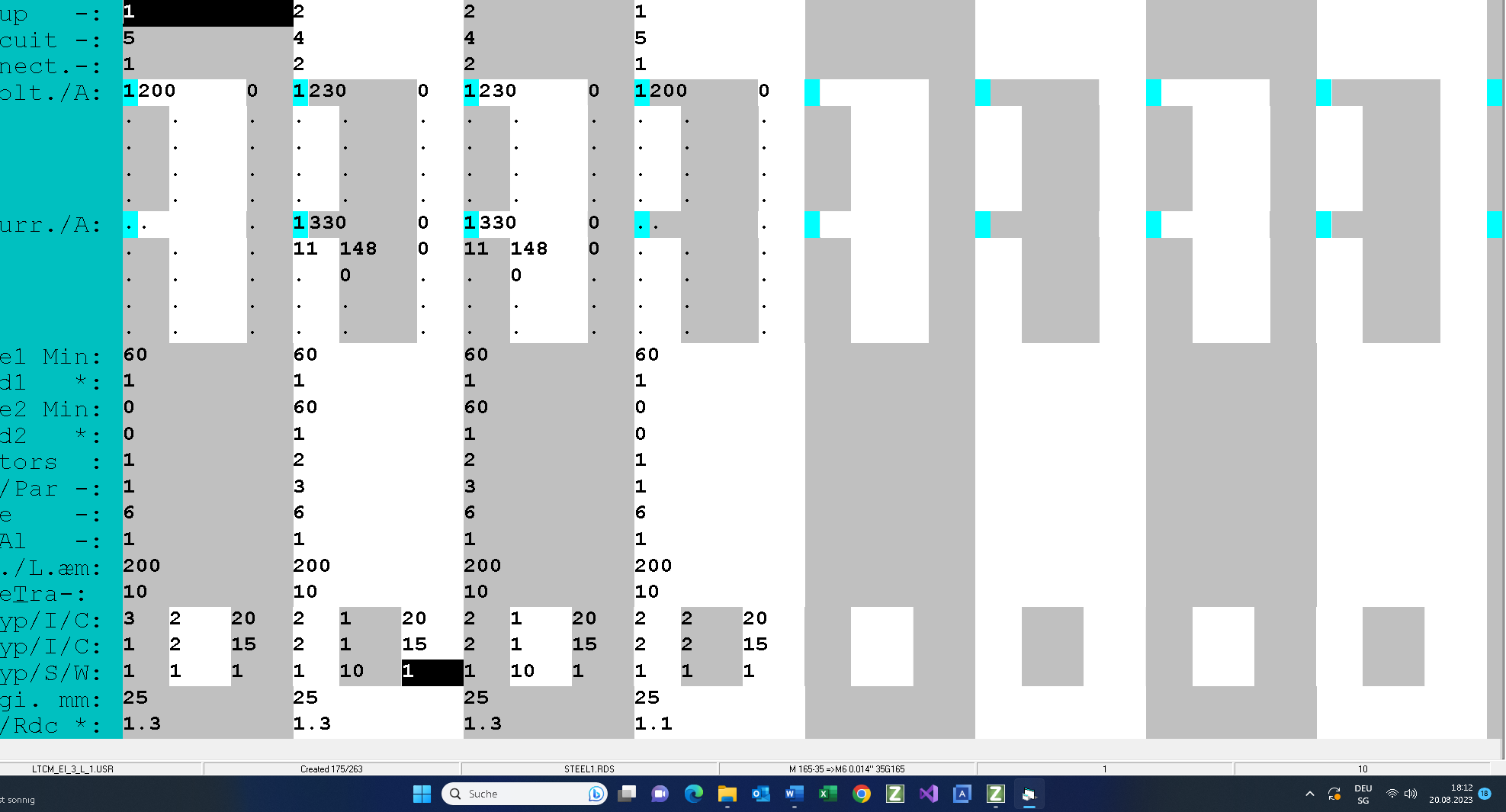

Parameters of windings per leg:

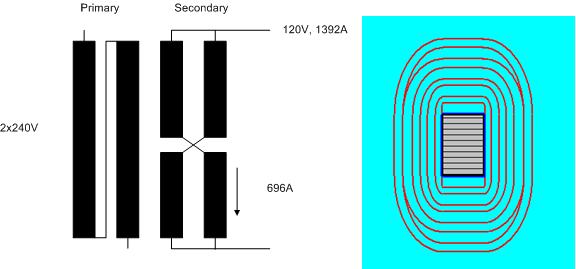

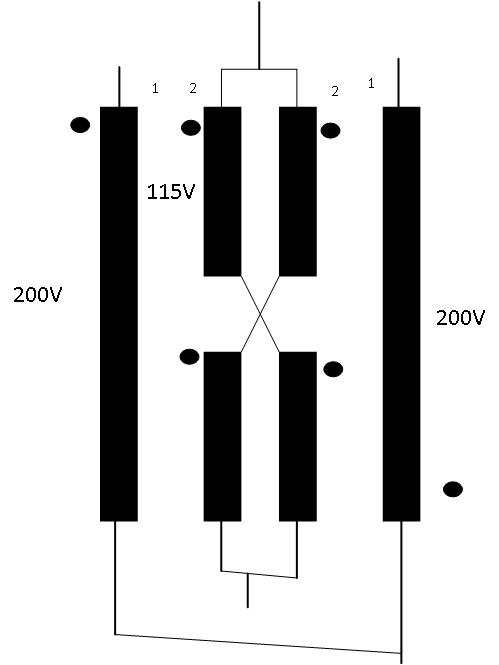

Schema

In this connection of the cross secondary windings the current distribution through both secondary windings is equal.

“Sandwich” order of the windings reduces the leaking magnetic field through the windings. It limits the eddy current losses and the mechanical pressure in short circuit operation mode.

The cold value of the short circuit voltage has to limit the mechanical pressure in the windings during the short circuit operation mode under 60 N/mm2.

The inductance of the primary winding is bigger and the inrush current is lower.

Primary

The primary is created with 2 windings connected in series . The sine wave input voltage is 400V (200V per winding).

There is no duty cycle operation mode and there are no sectors.

All surfaces of the primary are cooled via the cooling channels of 15mm (inside of the core window) and 20mm (outside of the core window). The space between the yoke and the primary windings is 25mm With the eddy current losses factor (RacRdc) 1.1 and 1.3 shell be limited the number of the round wires per litz.

Secondary

The secondary is created with 2 windings connected in parallel . The sine wave output voltage is 230V.

The rms current per winding is 362Arms. Normally there is no explicit information about the current harmonics in a K-factor transformers. The designer has to create a combination of the first current harmonic and 11. current harmonic in order to satisfy the following conditions:

I1^2 + I11^2 = Irms^2

1^2*I1^2 + 11^2*I11^2 = K-factor* Irms^2

For Irms = 362Arms and K-factor = 20 the calculated current harmonics I1 and I11 are:

I1= 330Arms

I11 = 148Arms

Also there is no duty cycle operation mode on the secondary side.

In order to avoid the circulating currents between 2 parallel connected secondary windings each of them is created with 2 cross connected sectors (view the schema above).

Once again, a 500kVA transformer for K-factor = 20,the short-circuit voltage >1.5% , low inrush current factor <8 and the efficiency >98.5% (Windings losses <1.2%, core losses < 0.3%) can be optimal designed and manufactured. With the eddy current losses factor (RacRdc) 1.1 and 1.3 the number of the round wires per litz shall be limited. Note that at this point of design you can not prescribe the wire size. You can select only the wire family which the program has to use in order to select the suitable wires for your application.

The first secondary winding is cooled via the cooling channels of 15mm (inside of the core window) and 20mm (outside of the core window). The second secondary winding has only two 20mm cooling channels outside of the core window. It is better cooled than the first secondary winding and therefore it is in a good thermal connection within the core window with the first secondary winding.

The space between the yoke and the secondary windings is 25mm.

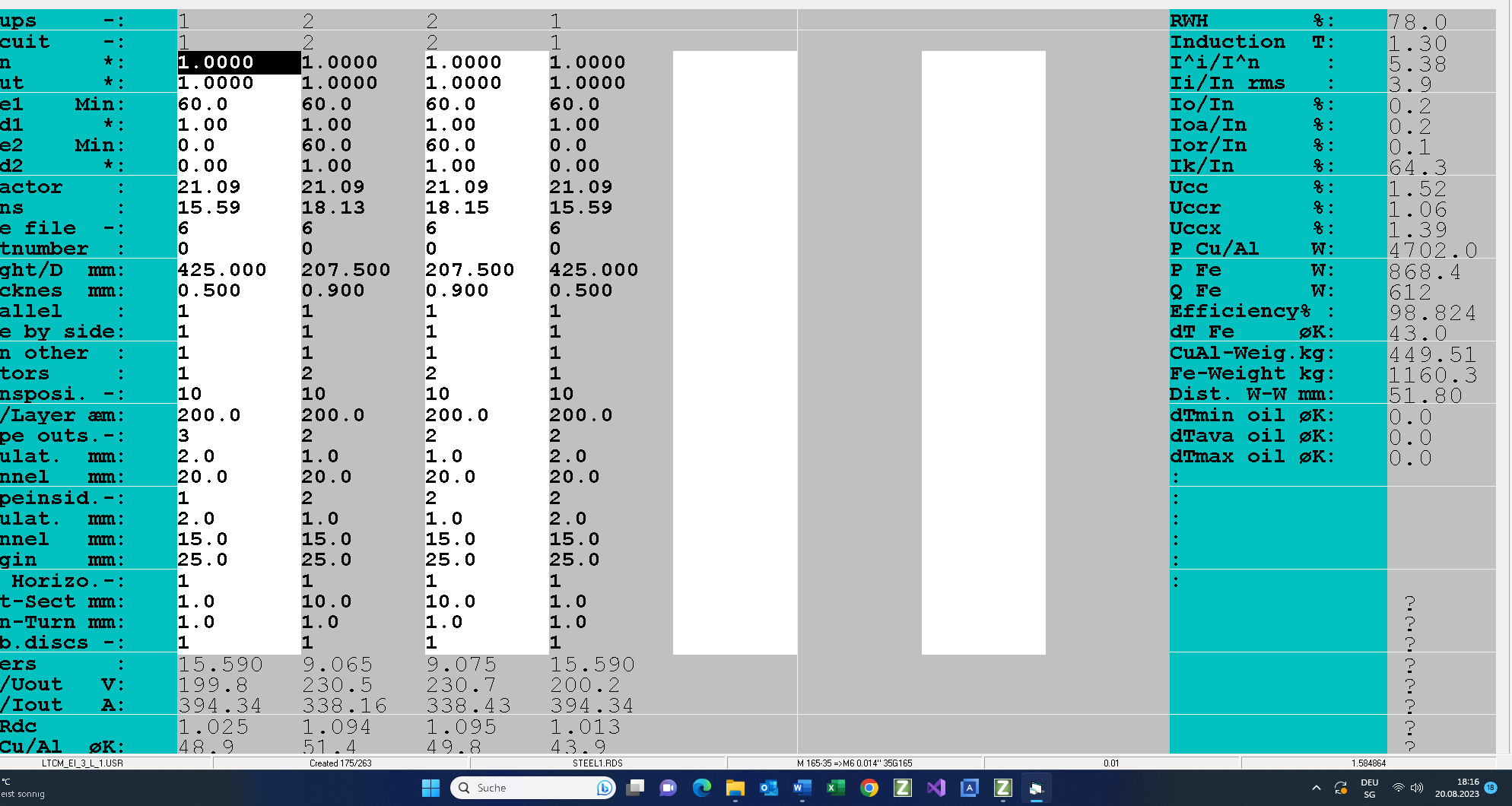

Core

On this input screen you can :

- select and manipulate the selected steelM165

- set the operating induction (1.30T, low to limit the inrush curren) and the frequency (50Hz)

- select the core assembly =6 (45°)

Environment

The cooling medium is air with the ambient temperature 60°C. The cooling factors for the convection and the emission are set to 80% because the transformer will be placed in a cabinet.

The cooling surface of the core is increased by using 4 L-brackets on the core.

The impregnation is practically “dry” because there is only 10% varnish (90% air) in the windings and in all the gaps between the insulations and the layers of the windings

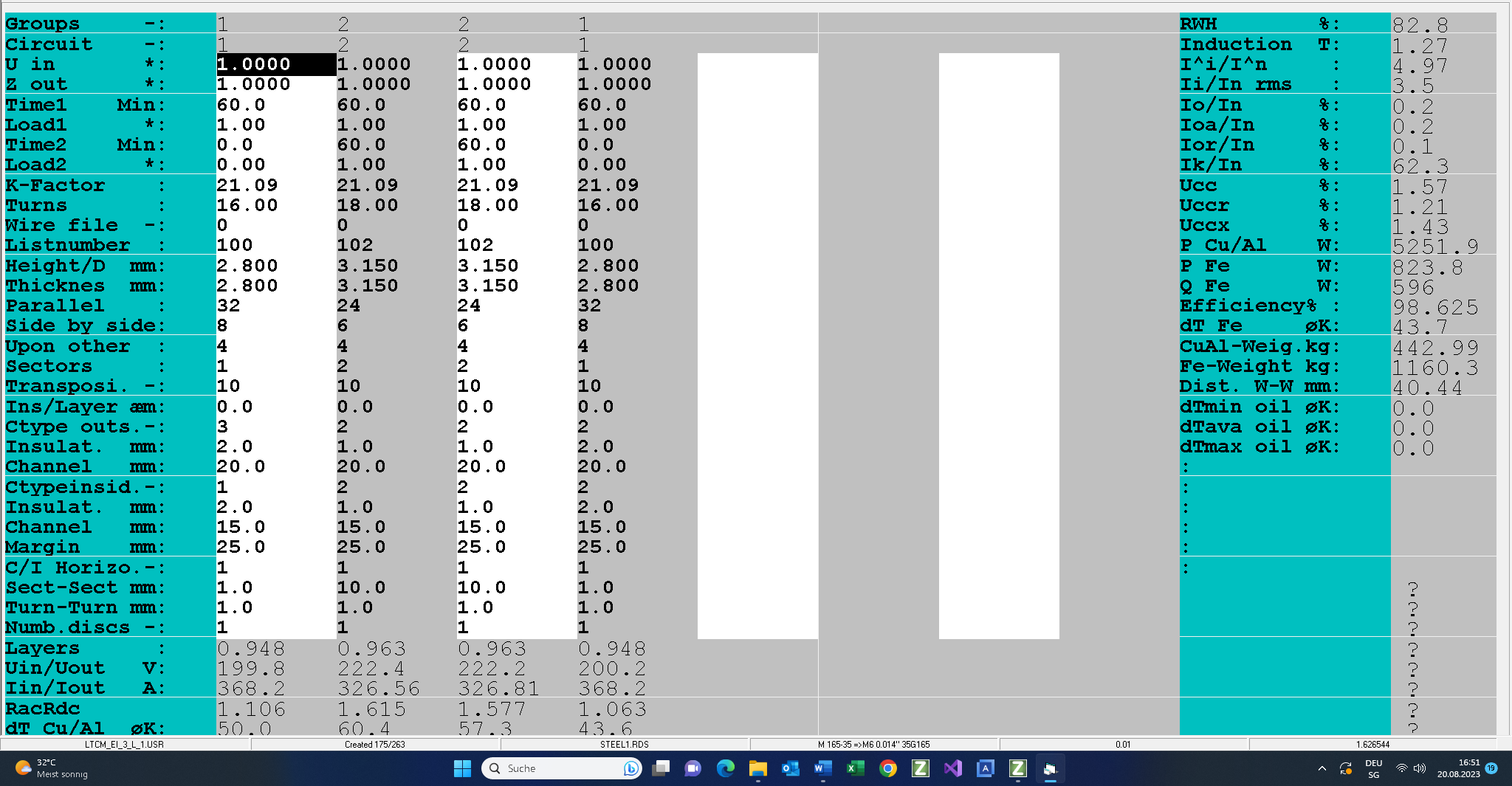

Input screen with litz

Test mode with litz

In the test mode we have modified the rectangular litz form in order to get better winding fill factor.

Print the results by clicking on the following link.

Here are the most important design results

The build is 83%

Short circuit voltage cold 1.57%

Max. mechanical pressure in short circuit 52 N/mm2

Efficiency is 98.7%>98.5%

Max. winding temperature is 120°C.

Version with Cu foil

We use the same parameters as in the previous design.

In the Test mode we change the calculated foil dimensions:

Here is the result of the design with Cu foil: Click on the following link (PDF).

NOTE:

If you are going to design a transformer for K-Factor <13 we would recommend to use the following schema: