GET YOUR RALE INPUT FILE (click): A_Rale_Input_File_003

How to design a not short-circuit-proof

18VA – low profile safety transformer as per IEC 61558,

protected by a miniature fuse in accordance with IEC 127

Technical specifications relevant for design

Electrical data

| Input Voltage: | 230V, +10% -10% sinusoidal |

| Frequency: | 50Hz |

| Nominal output voltage: | 24Vac |

| Nominal output current: | 0.75Aac |

Environment and operating conditions

| Ambient temperature: | 70°C |

| Mode of operation: | Continuous |

| Test conditions: | Not short-circuit-proof, protected by miniature fuse to IEC 127 |

Additional specifications

- Safety transformer as per IEC 61558

- Insulation class B

- Potted in the case

- Core and bobbin UI 39/13.5

Design criteria

IEC 61558

A transformer which is not short-circuit-proof as per IEC 61558, is not equipped with a cutout. However, the manufacturer is obliged to inform the user of the required safety measures by means of which the transformer must be protected in operation. In this case, the transformer should be protected by means of a miniature fuse as per IEC 127: The type and current rating of the fuse must be stated on the transformer label.

With the selection of a fuse on the primary side, optimal protection is achieved both against overload and short circuit.

If the selection of fuses on the primary side is affected by the inrush current, then an overload protection fuse is used on the secondary side.

Testing

The procedure for testing goes as follows:

Firstly the transformer is loaded with the nominal resistances and with a voltage of 1.1 times the nominal input voltage until permanent operating temperature is reached. In this context, the temperature of the windings must not exceed the value of Tnominal.

Immediately after this test, all secondaries are loaded for period T at K times the nominal current of the fuse. Period T is the longest pre-arcing time of the fuse, caused by K times the fuse’s current rating. After time T, the temperature of the windings must not exceed the value of Tmax. The typical values for a slow-blow miniature fuse as per IEC127 are:

T = 60 minutes

K = 1.6

Here, the temperature of the windings must not exceed Tmax and that of the case must not exceed the values set out in the following table. In the case of transformers with regulation > 20%, the inrush current is not a criterion for the choice of fuse. For that reason, it is possible to prescribe a quick-blow fuse, which would have resulted in a much shorter pre-arcing time.

Finally, all output windings are short-circuited. At 1.1 times the nominal input voltage, the integral thermal cut-out must actuate, before the temperature exceeds the value of Tmax as per the following table:

| Insulation class: | A | E | B | F | H |

| Typical re-arcing time T in (minutes): | 60 | 60 | 60 | 60 | 60 |

| Typical factor K: | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Max. winding temperature in test Tmax (° C): | 200 | 215 | 225 | 240 | 260 |

| Max. winding temperature in nominal operational mode Tnominal (° C): | 100 | 115 | 120 | 140 | 165 |

| Max. case temperature (° C): | 105 | 105 | 105 | 105 | 105 |

Insulation class

In these output ranges, the bobbins, the case, and the potting compound are employed exclusively together with insulation categories E and B. Wire insulation and insulation foils are very often employed in insulation class F.

==> We select insulation category B.

| Max. winding temperature in nominal operational mode: | 115°C |

| Max. winding temperature in test mode: | 215°C |

| Max. case temperature: | 105°C |

Important note: The program will design the mean case temperature!

Ambient temperature

Normally, the transformer is operated in an environment whose temperature is between 25°C and 80°C. Very often, we encounter an ambient temperature of 40°C and 70°C.

==> For this calculation, the ambient temperature is defined as 70°C.

Case

For safety reasons, low-profile-constructed safety transformers are almost exclusively potted in vacuum in a case. The main advantages of a potted transformer are:

- The transformer is cooled better.

- You can use a bobbin without high wall thicknesses and without large leakage paths, but with a larger winding space.

- On large production runs, there is no problem in inserting the core insert with regard to the question of mechanical robustness and of humming of the core plates.

==> Let us design a transformer potted in a case:

Thermal resistance of the potting compound

The potting compound which is best from a thermal viewpoint, and is also the most expensive, has a specific thermal conductivity of 0.8W/m/°K. In practice, we usually operate with a potting compound whose thermal conductivity is 0.4/W/m/°K.

==> We have chosen a potting compound whose thermal conductivity is 0.4W/m/°K.

Bobbins

In this output range, recourse is had almost exclusively to a double-chamber bobbin. From the viewpoint of design, only the dimensions of the bobbin are important. A bobbin with increased insulation or large leakage paths has a smaller winding space and a smaller cooling surface area.

==> We have selected a double-chamber bobbin from a family of bobbins with a large winding space.

Impregnation

In this topic there is the possibility of potting just the bobbin or the window of the core, or of injection under pressure. With this method, we save a quantity of potting compound for the same voltage resistance in the potted transformer, and we don’t need a case.

==> Our transformer is potted in a case in vacuum.

Sheet quality

A flat transformer must be as flat and as small as possible. For that reason, these transformers are manufactured exclusively in UI sheet form and annealed, grain – oriented core quality with specific Fe-losses of 1.11 W/k at 1.5T and 50Hz (WV111, M6X, …).

==> We have selected the annealed, grain-oriented core quality of 1.11 W/kg at 1.5 T, 50 Hz, 0.35 mm thick, sheet form UI 39, without holes in the corners.

Induction

These transformers are manufactured with an induction in nominal operation of between 1.5T and 1.7T (!). No-load induction is normally above 1.8T. For that reason, we must use an annealed, grain-oriented core quality without holes in the corners.

Additional tolerance for output voltage

The output voltage of a not short-circuit proof transformer is tested in the hot state at nominal primary voltage and nominal load resistance.

==> We are going to perform our design at the nominal output voltage.

Procedure for design

If you are not yet familiar with Rale Design Software, then please read the text: “How do I design a small transformer?” in DESIGN EXAMPLES. You should keep a copy of this text within your reach when performing design operations.

- Start your program and load up the attached input data file. This input data file has all of the most important presets for designing a not short-circuit-proof transformer of insulation class E (((ABER OBEN HATTEN WIR B!!!))), which has to be protected with a miniature fuse as per IEC127.

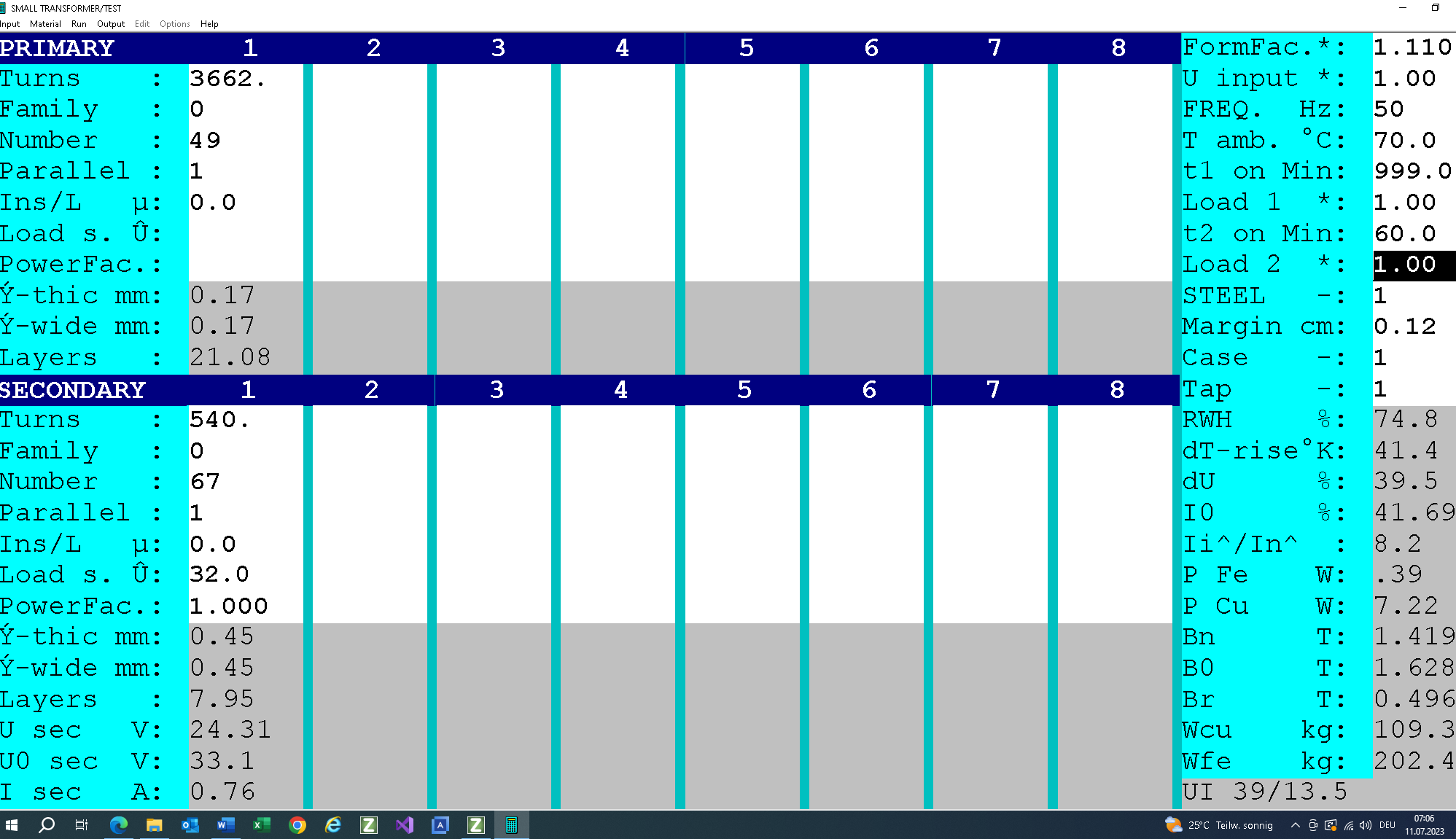

2. Fill in your input mask as follows. If you need help, then press function key F1. For each input field, there is extensive description. In the case of this input data file, the preset ambient temperature is 40°C. Correct the input values for ambient temperature and temperature rise as per the above diagram. The temperature rise employed here is 10°K lower than permitted.

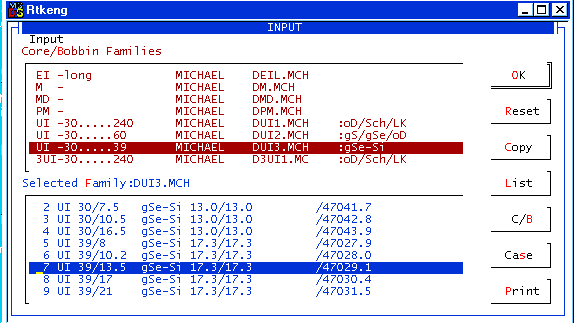

- Select the core and bobbin with the correct case. If the dataset for the core and bobbin which you selected has no case, then you have to set up the case yourself. The core selected in the following illustration has a case in its dataset. For this reason, it is enough to mark the core UI39/13.5 and to click on the OK button.

4. Click on OK.

5. After the design procedure has been completed, the following design data is available and can be printed on 3 pages (click on the link):

The next step is to check the calculated data.

– Firstly, we check whether the maximum winding temperature in the nominal operating mode at 10% overvoltage is: ambient temperature + dTprim in overload = 70 + 49 = 119<120°C.

– Then we check whether the maximum winding temperature in overload mode AT 10% overvoltage is: ambient temperature + dTprim in overload = 70 + 121 = 191<215°C;

– The selection of the fuse nominal current, on the primary side, has to be between 0.13A and 0.14A and its I*t has to be bigger than 0.63^2*0.02, where 0.63 Arms is rms inrush current during first 20msec or between 0.825A and 0.9 A, on the secondary side.

– If the nominal fuse current is outside of the prescribed range, you have to use the new K = 1.6*If/Inom >1.7 and recalculate the transformer.

– The mean case temperature in overvoltage mode is: ambient temperature + dT case in the operation = 70 + 42.5 = 112.5>105°C. This means that this transformer has to be installed in a unit such that it cannot be contacted during operation.

If the design data is not satisfactory, there are two ways to implement the desired correction:

– We can go back to the input mask (function key F2), correct the input data and re-design the transformer or

– We can go back to the test program (function key F5), modify the designed transformer manually and correct the transformer in that way.

After completion of the design work, we can print out the design data on-line or store it on the local PC and print it off-line. The output data file from this design example RaleOutput_003.PDF is supplied together with this document. Copy it into the directory in which your Rale Demo Programm is installed: