CLICK TO GET INPUT FILE: RaleInput_007

How should one design a low inrush current universal control transformer for 800VA continuous output power

as per IEC 61558 ?

Technical specifications relevant only for design

Electrical data and schema

| Input voltages sinusoidal | 210V, 230V, 250V, 380V, 400V, 420V |

| Frequency | 50Hz |

| Nominal output voltage | 230V |

| Max. no-load voltage | 253V at nominal input voltage |

| Nominal output current | 3.47A (800VA) |

Ambient and operating conditions:

| Ambient temperature | 40°C |

| Mode of operation | Continuous operation |

| Test conditions | Non-inherently short-circuit proof, Safety transformer class E, overload protected by thermal fuse in the primary winding and short circuit protected by miniature fuse on the primary side. |

Design criteria

There are 2 design criteria:

-Regulation <=10%

and

-max winding temperate at overvoltage <=115°C

| Insulation class | A | E | B | F | H |

| Max. winding temperature in test T max (° C) | 200 | 215 | 225 | 240 | 260 |

| Max. winding temperature in nominal operating mode T nominal (°C) | 100 | 115 | 120 | 140 | 165 |

| Max. voltage increase (%) | 10 | 10 | 10 | 10 | 10 |

Bobbin

Control transformers have to be made with a low internal resistance and a low leaking impedance. For that reason, control transformers are constructed exclusively with single-section bobbin.

Note that the primary is wound outside (PS-Order =2)

Induction and Fe-quality

Low Inrush-current transformers are operating at a low induction (1.2T-1.3T). In the output range up to approximately 200VA, cold-rolled Fe quality 5.3W/kg at 1.5T, 50Hz. Over and above that, we find cold-rolled Fe-quality 4.00W/kg at 1.5T, 50Hz and grain-oriented Fe-quality 1.11W/kg at 1.5T,50Hz.

Inrush current

The peak value of the inrush current in the first period after switch-on at the zero-axis crossing point should not exceed a factor of 15 x the peak value for nominal input current. This can best be achieved if:

- The nominal induction is 1.2T-1.3T.

- The core is constructed with a defined gap of approx 0.05-0.10 mm, so as to reduce residual magnetism (remanence): Gap = 2 (=0.05 mm), Core assembly = 2

- The primary winding is routed to the outside.

Design procedure

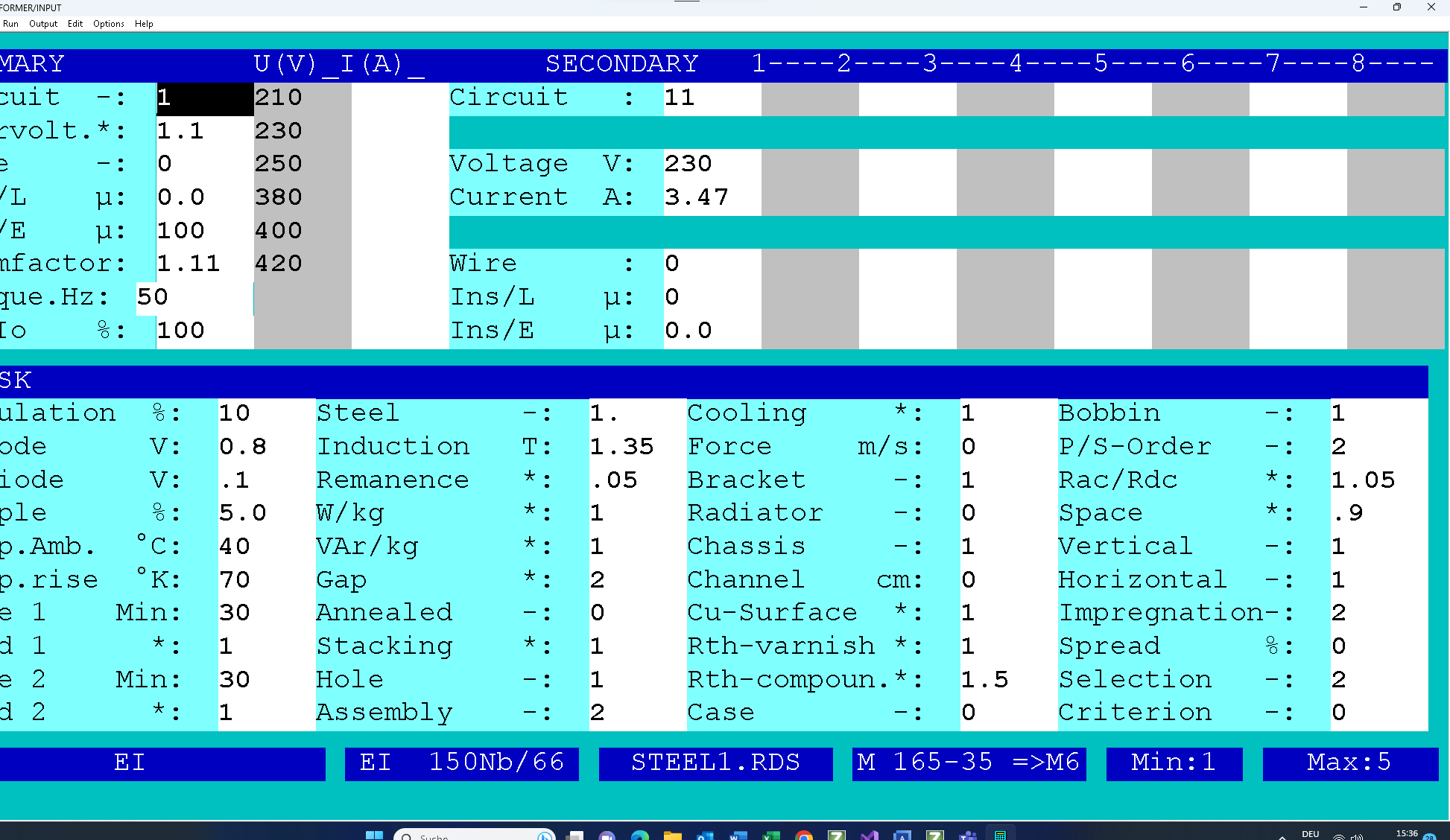

Fill in the design input mask as follows. If you need any help, press function key F1. There is extensive description for each input field.

Note that the core&bobbin are selected by hand out of the existing data base: over 5000 units.

On completion of the design work, the following design data will be available and can be downloaded and printed (click on the following link).

This is followed by checking of the design data:

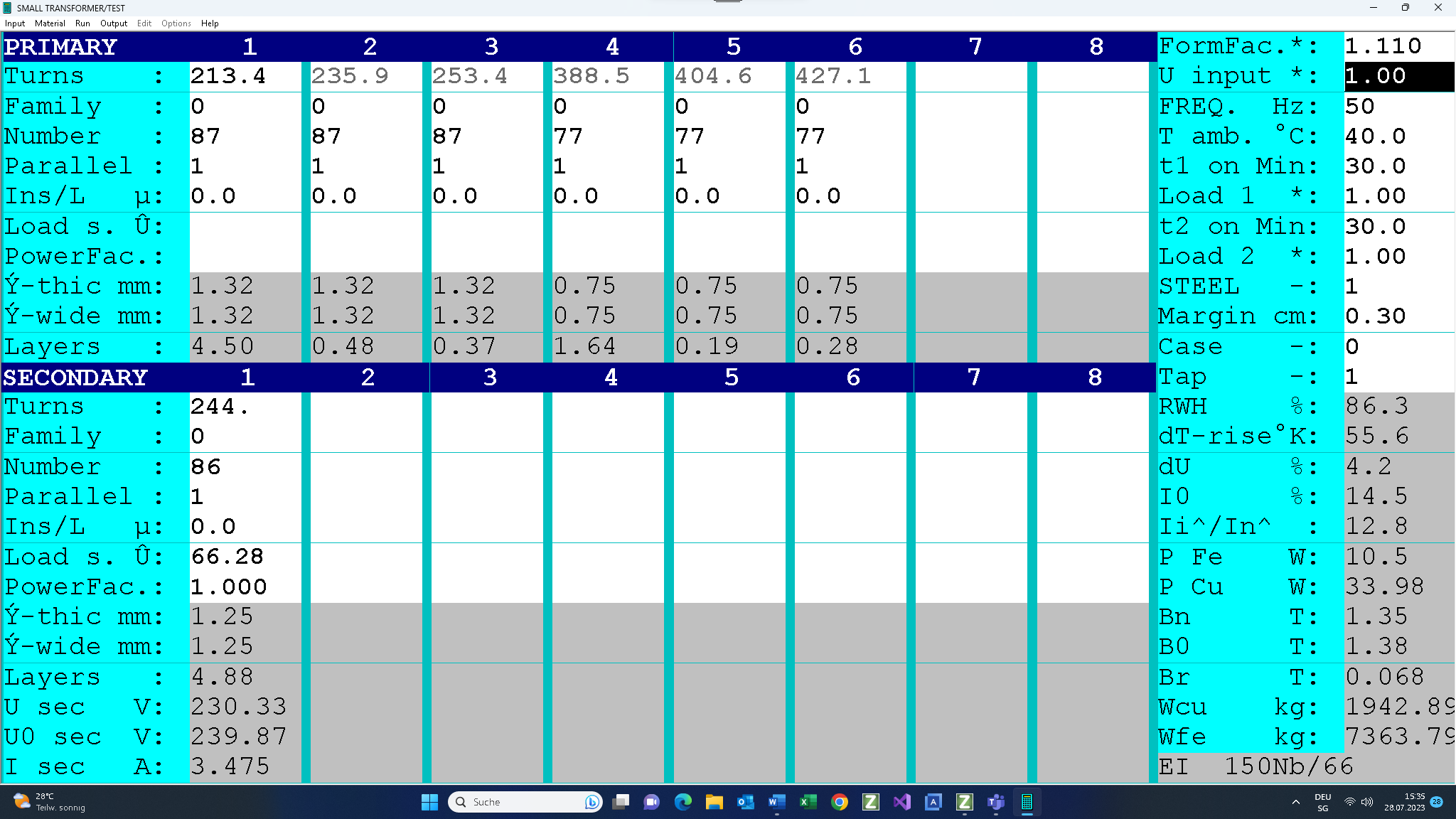

- We now check the winding data and the filling factor (86<100%).

- The maximum temperature of the windings is 40°C+67.5°K = 106.9°C < 115°C.

- Regulation = 4.42% < 10%.

- The inrush current factor is 94/4.45/1.41=14.915.

This is followed by checking of the output voltage at the nominal input voltage of 230V: U in = 1.

Now you can download and print the results by clicking on the following link.

If the design data is not satisfactory, then there are two ways by which we can implement the desired correction:

- You can return to the input mask (function key F2), correct the input data and redesign the transformer.

- Or you can access the test program (function key F5), modify the designed transformer manually and redesign the transformer by that means.

On completion of the design work, you can print out the design data on-line, or save it on your local PC and print it off-line.