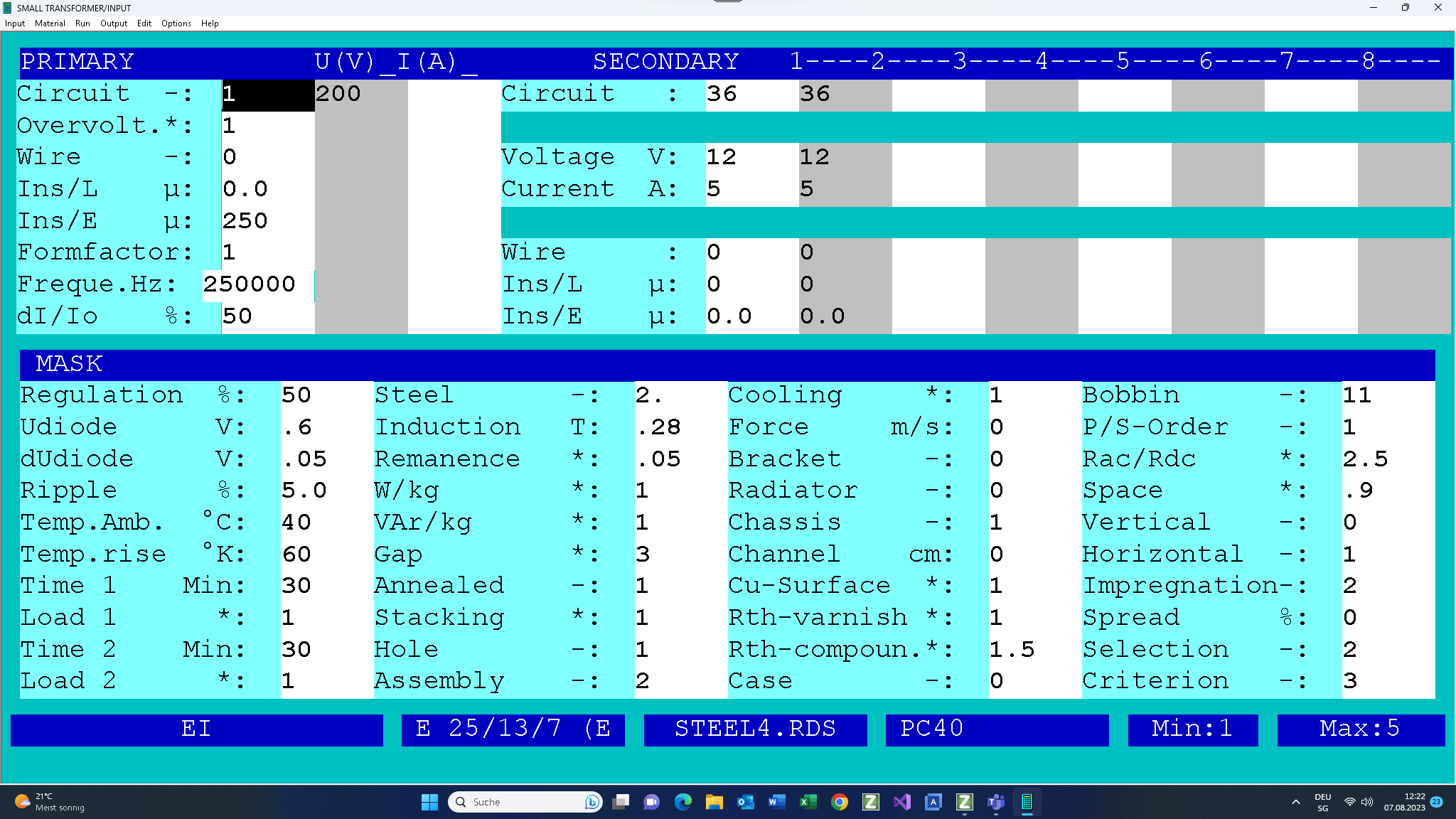

CLICK HERE TO GET INPUT FILE: RaleInput_011

How should one design

a 250kHz, 120W forward transformer with voltage controller,

for input voltage range 200V to 350V,

as per IEC 61558?

Technical specification relevant only to design

Electrical data and scheme:

| Input voltage | 200Vdc – 350Vdc (Bridge rectifier with RC-load, for input voltage 230Vac+10%-20%, 50Hz) |

| Frequency | 250kHz |

| Nominal output voltage | 2 x 12Vdc, automatic controlled on the primary side |

| Nominal output current | 2 x 5Adc, -50% |

| Ripple of the input current | Max. 50% at the maximal input voltage and the nominal load |

Ambient and operating conditions:

| Ambient temperature | 40°C |

| Test conditions | Non inherently short-circuit proof |

| Mode of operation | Continuous |

Specifications:

Insulation class E

The following forward transformer diagram illustrates only parameters relating to design. The windings for recuperation and for measurement cannot be calculated by program.

During the initial half period a normal AC transformer is powered by positive voltage, and during the second half period by negative voltage. The values of the voltage-time surfaces of both voltages are the same. This changes the induction in the core of the AC transformer from -Bmax to +Bmax.

In the case of a forward transformer, the primary winding Wp during the initial switching period q*T is connected on the voltage Up. In this time the induction rises from Br to Bmax. During the second switching period the recuperation winding Wr is fed to the same input voltage Up. In this time the induction falls from Bmax to Br. (Br is remanence)

During the switch-on phase q*T the magnetizing energy is stored im the winding Wp.,. Itis returned to the feed source via the rce recuperation winding Wr. There are several layouts which can be used to realize the recuperation. For this reason, and because the structural performance of this winding is normally only approx. 5%-10% of the structural performance of the winding Wp, this winding is not calculated with the program. The user calculates it manually.

During the first phase the primary voltage Up is fed to the primary winding Wp. The primary voltage increases the current IL through the choke L and the magnetizing current io through the primary winding Wp. The voltage lies in the secondary winding:

Us = (Uo+Udiode) / q.

During the second phase the primary winding WP is disconnectes from the primary voltage Up. The magnetic energy which is stored in this is returned via the winding Wr. The number of turns Wr in this winding is chosen to ensure that the conditions:

q + r < 0.8-0.9

and

r = q * (Wr/Wp)

The relative switch-on duration q is chosen to be between 0.40 and 0.60 at minimum input voltage. This produces:

r < 0.3 – 0.6

or

Wr = (0.5 – 0.66) * Wp

During the switching period q*T, the induction changes by pulsing between Br and Bmax. The choice of Bmax depends on the ferrite type and on the operating temperature. By an air gap in the core.the residual induction Br can be set practically at a value between 5% and 10% of the Bmax induction. With an external source or a permanent magnet it would be possible to set a negative residual induction.

The ripple of the current through the choke L affects the effective value of the transformer current.

Ripple = 100 * (Ilmax-Ilmin)/Ilmax+Ilmin)

This value must be notified by the user.

Criteria for design

A high-frequency transformer with non- inherently short-circuit proof as per IEC 61558 is equipped with a safety. Very often we arrive it at a combined protection solution consisting of a thermal fuse in the primary winfing against overload and of a miniature fuse on the primary side as short-circuit protection. For this reason, short-circuit and overloads are not design criteria. The criterion for design with regard to IEC 61558 is only temperature Theta nominal.

| Insulation class | A | B | C | D | E |

| Max winding temperature in nominal operating mode | 100 | 115 | 120 | 140 | 165 |

Insulation class

Max winding temperature in nominal operating mode = 115°C

Criterion for design

Normally, high-frequency transformers have very low regulation and are designed according to the prescribed temperature rise.

Since these transformers are manufactured almost exclusively using ferrites, the optimum operating temperature is around 100°C.

Bobbin

In order to protect the transistors, high-frequency transformers should be manufactured for low leaking reactance, with single-section bobbin . For this reason, we very often arrive at litz or interleaved windings.

Ferrite quality

Since the optimum operating temperature of ferrite for high-frequency transformers over 100VA is around 100°C and their ambient temperature is between 40°C and 70°C, our design assumption must be for a temperature rise of between 30°K and 60°K. If the core losses in relation to temperature rise are not economically acceptable, then the c program will optimize or reduce the AC-component of the induction automatically. But this does indicate that the selected ferrite quality is not optimized.

Induction and ferrite quality

High-frequency transformers are equipped almost exclusively with ferrites. The program calculates both the active and the reactive core losses by hypothesizing the ferrite type, the frequency, the form of input voltage, induction and core temperature. The induction should be selected such that the transformer does not saturate at maximum input voltage and maximum core temperature.

Copper additional losses

With a high-frequency transformer, the distinctions are drawn between the following additional losses in a winding, over and above the dc-current losses:

-Eddy current losses

-Displacement losses

-Proximity effect losses

-Losses due to circulating currents through the parallel-connected wires.

The input for Rac/Rdc will limit the extent of additional losses (eddy current losses). The program selects a high enough number of parallel-connected wires for the eddy current losses to fall short of the prescribed value for Rac/Rdc. For that reason, the input for Rac/Rdc is also used for monitoring of parallel-connected wires. The value is normally set between 1.3 and 3.

Losses of circulating currents through the parallel-connected wires are not calculated. It is assumed that these additional losses have been eliminated by suitable design precautions. In particular, it should be ensured, for a given litz, that the twisting for the winding is done such that a given wire has the same position at the input and at the output of the winding.

Nominal input voltage and relative switch-on period

The relative primary voltage switch-on period is defined as follows:

In the design of a forward transformer, the duration of the relative switch-on period (q = t1/(t1+t2) ) is taken into account indirectly via the input mode of the form factor:

Form factor = 1/(2*q)

A forward transformer with an automatic controller of output voltage is normally designed with the following parameters:

• “Nominal” input voltage Upmin = 200V.

• At this input voltage the relative switch-on period qmax will be 0.5 and the relative recuperation period rmin = 0.35.

• The form factor = 1/(2* qmax) = 1/(2*0.5) = 1

• Th relative switch-on period at the input voltage Upmax = 350V will be:

qmin = qmax * Upmin/Upmax = 0.5 * 200 / 350 = 0.285

Procedure for design

Fill in the design input mask as follows. If you need any help, press function keys F1. There is extensive description for each input field.

Note that the core & bobbin are selected by hand.

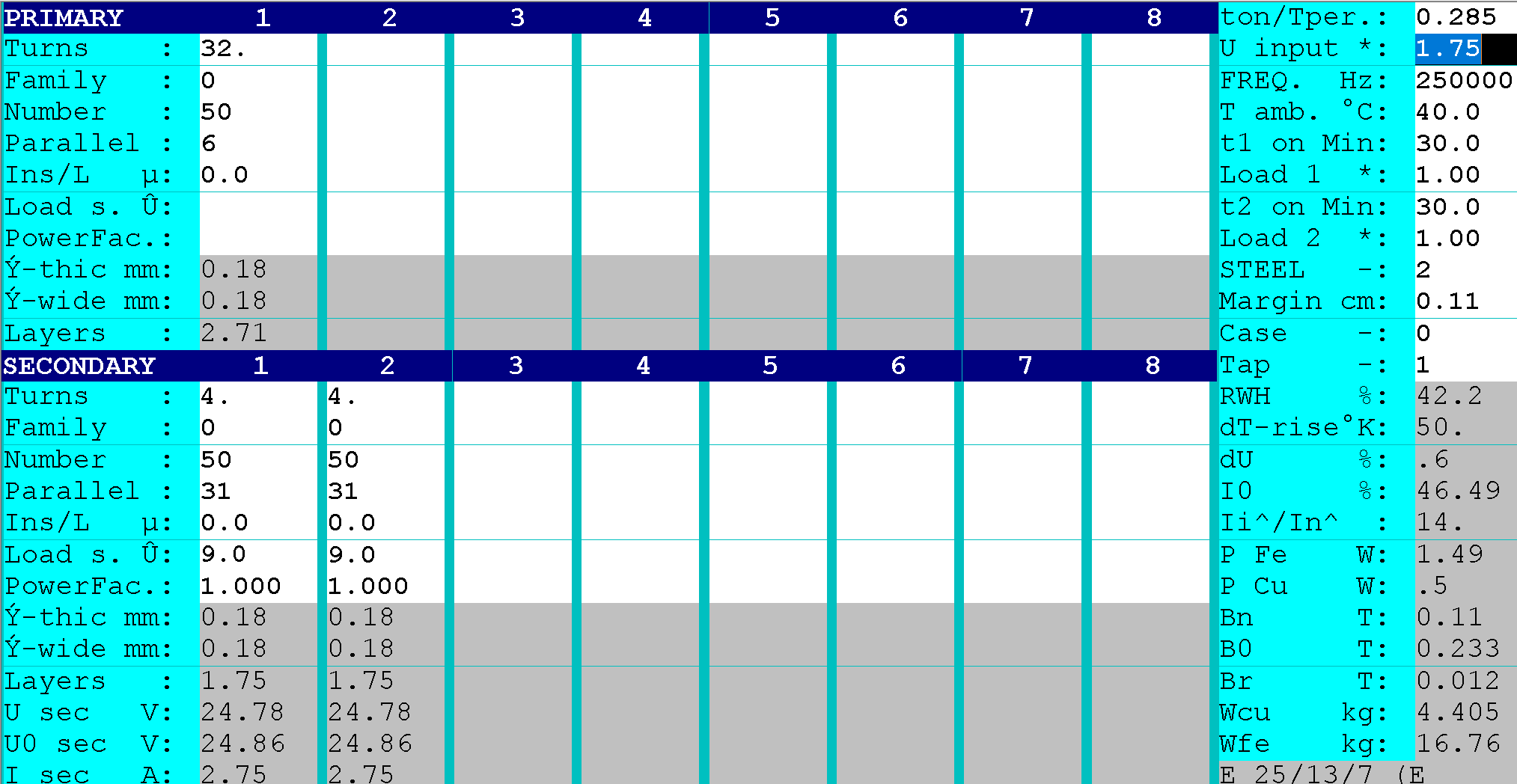

On completion of the design work, the following design data will be available, which can be printed on 3 pages (click on the link).

This is followed by checking the design data:

• We now check the winding data and the filling factor (42.2%<100%). With round litz form the cuild will be ca 60%.

• The maximum temperature of the windings is 40°C+56.9°K = 96.9°C < 115°C.

• The number of parallel-connected wires with 0.18 mm diameter is 6 and 31. Commercial considerations prompt us to select a litz of 5 wires of 0.16 mm diameter for the primary and a litz of 30 wires of 0.18mm for both secondary windings. This operation must be performed manually in the test mode.

• There now follows the configuration of the recuperation wturns Wr:

Wr = Wp * rmin/qmax= 32 * 0.285 / 0.5 = 18 turns

The number of parallel-switched wires is smaller than the number of parallel-switched wires in the primary winding Wp by the factor Iporms/Iprms.

6 * 0.367/0.986= 2 wires

Iporms => No-load current

Iprms => Primary nominal current

This is followed by checking of the output voltage for the maximal input voltage of 350V and the relative switch-on period of 0.285: Uin = 350/200 = 1.75 and form factor = 1/(2*0.285) = 1.754.

Note that the program controls your input in order to avoid the operation in the saturation of the core. If you get any problem with your input, proceed as follows:

• Increase the form factor to 1.754 (q = 0.285)

• Press F6 to recalculate

• Increase the input voltage to 350V : Uin = 1.75

• Press F6 to recalculate

or

• Decrease the input voltage to 200V : Uin = 1

• Press F6 to recalculate

• Decrease the form factor to 1.0 (q = 0.5)

• Press F6 to recalculate

Then the following PDF can be printed (click on the link).