How do we design a 60VA (long stack EI42/98) – non-inherently short-circuit proof safety transformer for halogen lamps in accordance with IEC 61558, protected by a thermal fuse ?Technical specifications relevant only for design

1. Electrical data and schema

2. Ambient and operating conditions:

3. Insulation

4. Scheme

|

5. About the thermal fuse

A non-inherently short-circuit proof transformer as per IEC 61558 is equipped with a thermal fuse to protect against short-circuit and overload. In this case, the transformer should be equipped with a thermal fuse.

The procedure for testing is prescribed as follows:

- Firstly, the transformer is loaded with nominal resistance and at 1.10 x the nominal input voltage until permanent operating temperature is achieved. In this context, the temperature of the windings must not exceed the value of Tnominal = 115°C.

- Next, all output windings are short-circuited. At 1.10 x the nominal input voltage, the integrated thermal fuse should actuate, before the temperature reaches the level of Tmax (in our current design Tmax is set to 125°C).

- The operating hysterese of the thermal fuse has to be tested: 125°C = off and 115°C=on , or similar

|

Insulation class |

A |

E |

B |

F |

H |

|

|

|

|

|

|

|

|

Max. average case surface temperature in test (° C) |

105 |

105 |

105 |

105 |

105 |

|

Max. winding temperature in nominal operation mode Tnominal (° C) |

100 |

115 |

120 |

140 |

165 |

|

Max. average case surface temperature in nominal operating mode (° C) |

80 |

80 |

80 |

80 |

80 |

6. Steel quality, core form and winding technology

For pricing reasons, transformers for halogen lamps are equipped with core quality M530 (5.3W/kg and 1.5T, and 50Hz).

The lamination of the used EI42/125 core are alternate stacked up to250 pieces. There are no holes in the corners.

Note that this core&bobbin do not exist in tha dat bse. You have to create it.

The double section bobbin with cover (view Weisser catalog) can be used “dry” for 4kV,50Hz,1min testing voltage.

7. Impregnation

Normally, a double-section bobbin unit is made with a cover such that the transformer can be manufactured “dry”.

8. Induction

These transformers are designed with an induction of between 1.3T and 1.5T in nominal operating mode.

9. Nominal output voltage

Normally, the nominal output voltage of transformers for halogen lamps is 5% lower than the lamps’ nominal voltage.

Design procedure

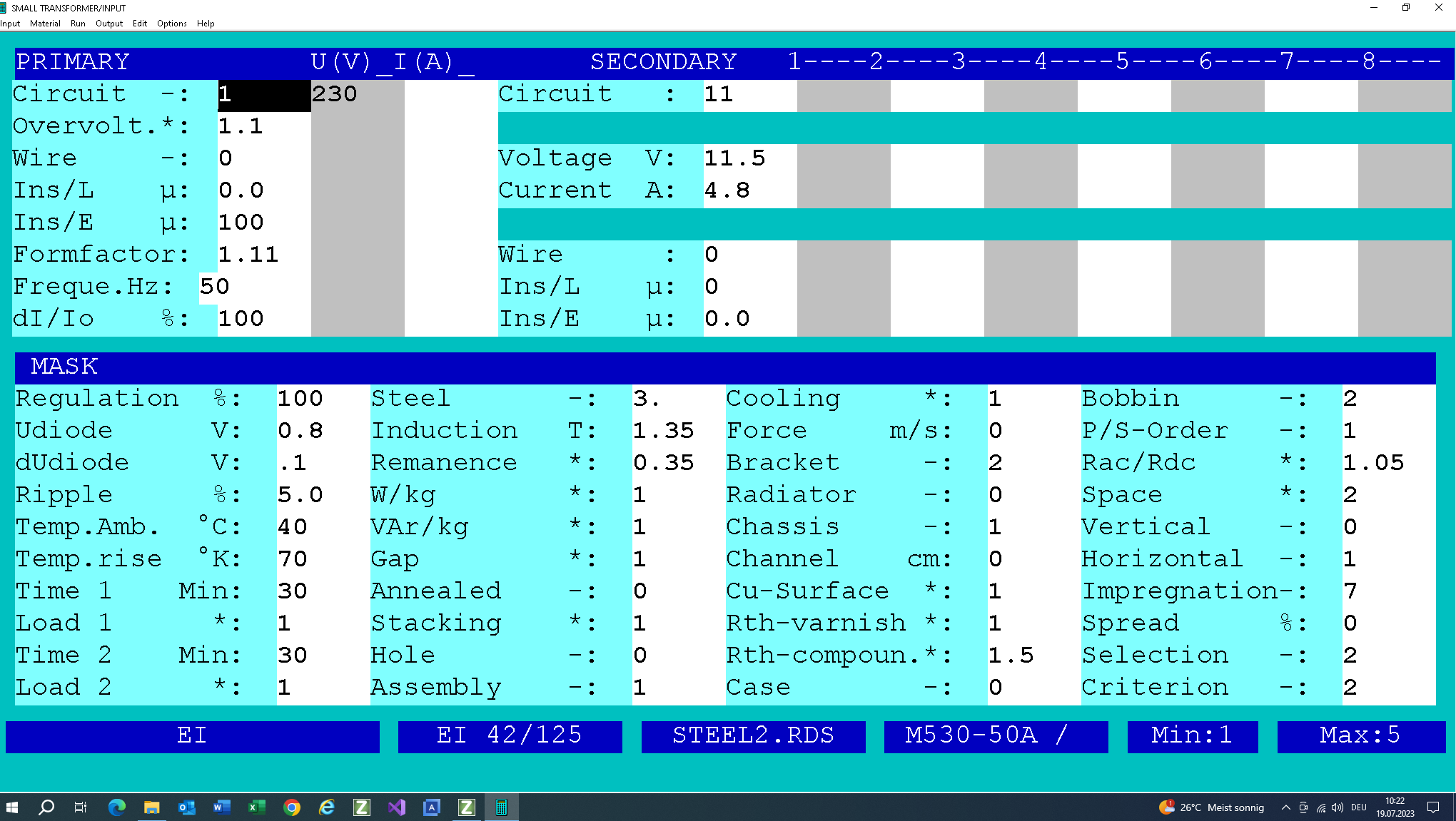

- Start the program to open the input screen and fill in the input mask as follows. If you need any help, press function key F1. There is extensive description for each input field. Or load the input file RaleInput_004.TK1.

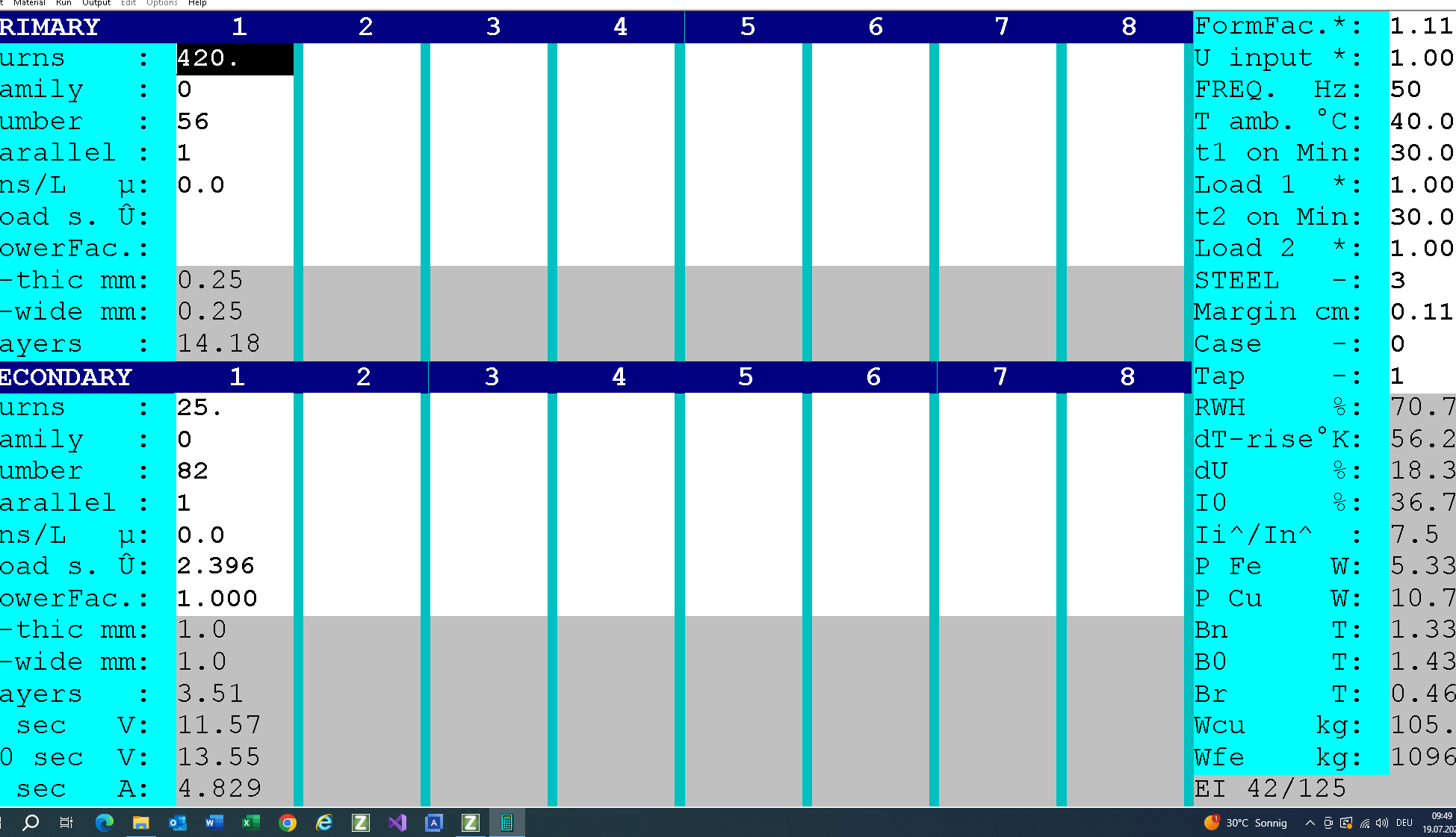

After completion of your design work, the following design data is available, that can be printed on three pages (click on next link):

This is followed by the monitoring of the design data:

- We start by checking the max winding temperature in overvoltage operation mode = ambient temperature + dTprim in 10% overvoltage operation mode= 40+70 =110 < 115°C

- Next, we check the winding data and the filling factor (70%<100%).

- If the design data is not satisfactory, then there are two ways to implement the desired correction:

- We can go back to the input mask (function key F2), correct the input data and re-design the transformer, or:

- We can access the test program (function key F5), manually modify the transformer design and re-design the transformer by that means. Here are the results at the nominal input voltage:

After completing our design work, we can print out the design data on-line, or save it on the local PC and print it out off-line. The output data file from this design example RaleOutput_004.PDF is supplied together with this document (click on the following link):